ibis

New Member

- Joined

- Dec 22, 2013

- Messages

- 13

Hi there,

I am a very happy owner of a PRS SE Bernie Marsden, but wanted to do something to prevent the wraparound bridge leaning forward in its studs. It does this because the bridge is a little thinner than the gap it locates into and string tension pulls it forward. The loose fit also means that it may fall out of the posts during string changes.

Reading the PRS forums, many users are resorting to locking bridge posts to resolve the issue of bridge tilt, the TonePros set being a popular option (although they have fit issues). I have come up with a much cheaper solution.

I took two of the very thin chromed steel washers that come with volume and tone control pots (I have a drawer full of replaced pots and their fittings; if you don't have any, I bet your nearest guitar repair shop will have lots), and cut once through each washer. The technique is to use wire cutters or pliers to 'score' the ring, then wiggle it either side of the weak point until it breaks. Then pull the two cut edges apart until you have a helical spring. The gap in the washer, that has been pulled open, will just about fit around the bridge post with some persuasion. Then its a matter of aligning the cut to the front of the posts (nearest the pickups) and sliding the bridge back into its slots. Its a nice tight fit and the opened washer acts as a spring washer as the bridge slides in, keeping it held in the posts for future string changes. There is very little, if any, bridge lean once the split washer has been installed.

I can't say if sustain is improved or if 'sitar like buzzing' is banished as I can't say I had noticed any problems with the bridge in the first place. I simply wanted to engineer a solution to the slant and prevent the bridge being loose during string changes.

I hope this helps anyone looking for a cheap solution, or perhaps someone like me who really likes the design, feel and intonation of the PRS SE wraparound bridge but just wants to slightly improve its fit.

Regards,

ibis

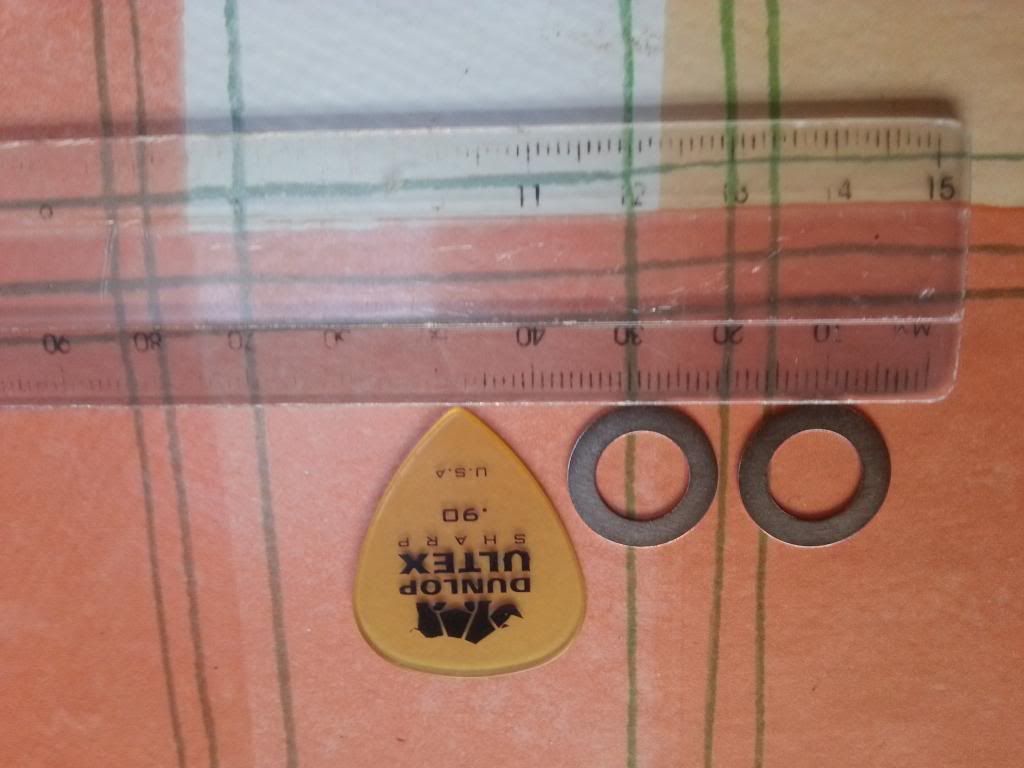

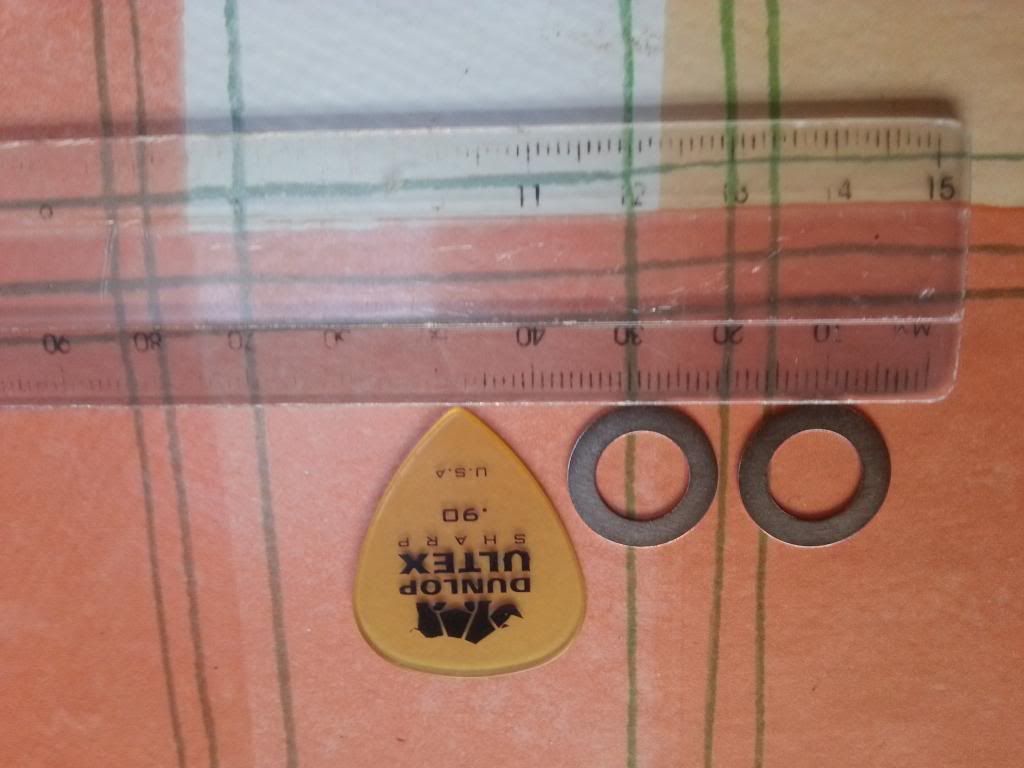

Here are some very amateurish pics of the process:

The washers

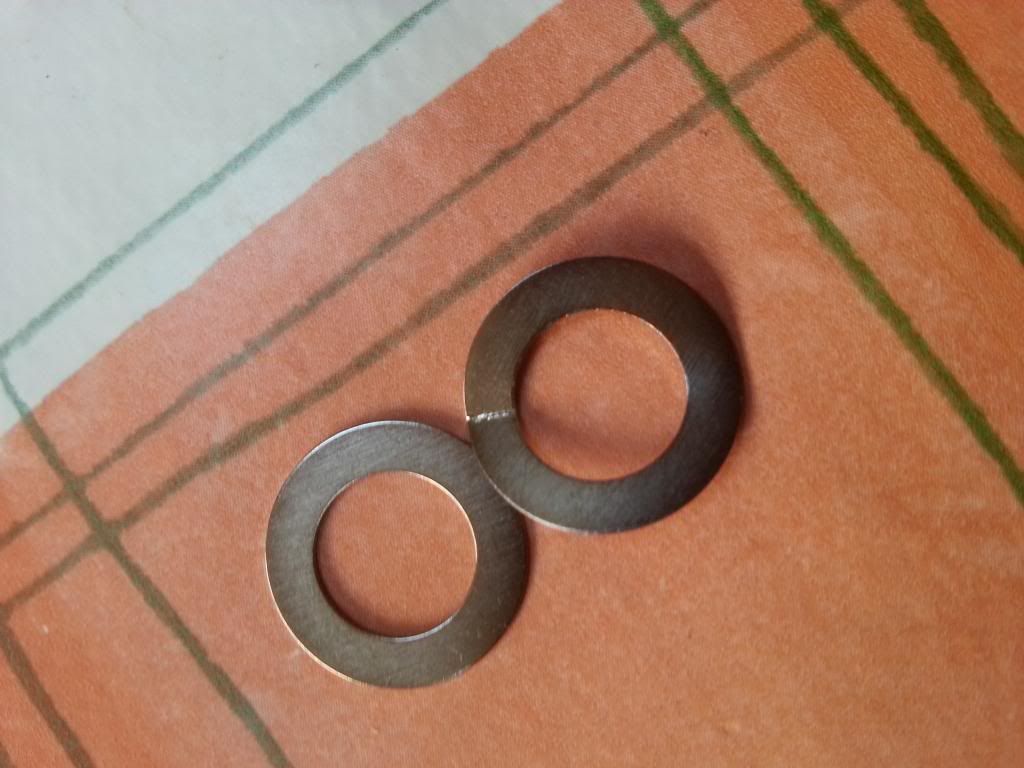

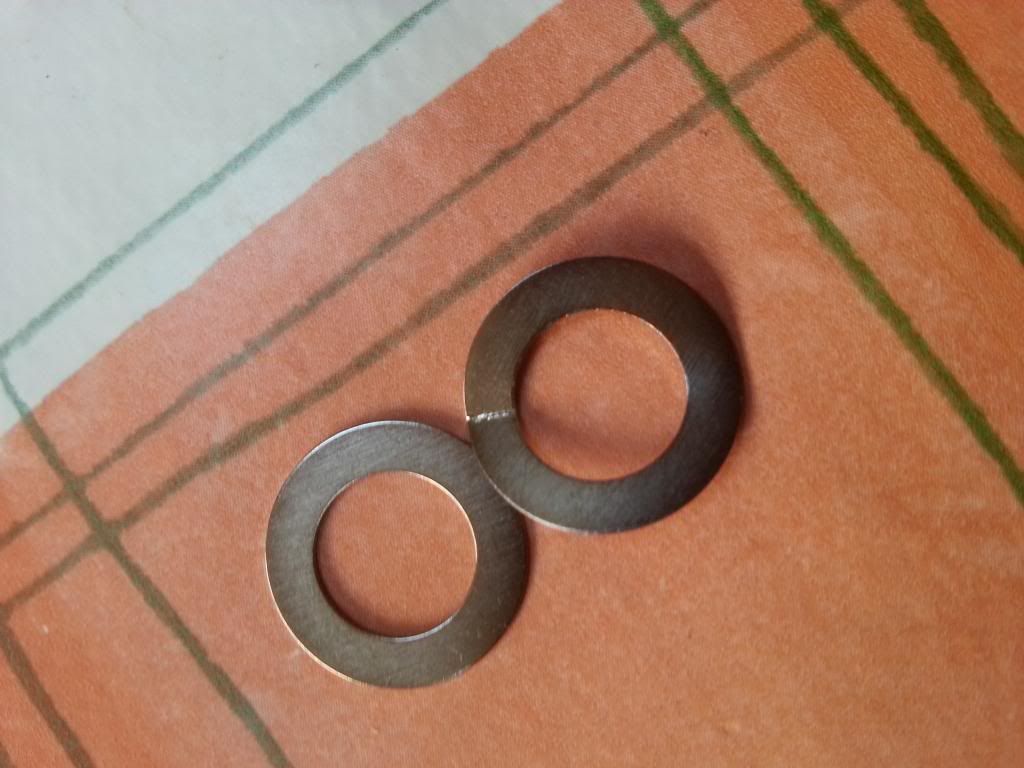

Scored with cutters:

One wiggled and split:

Persuaded to wrap around bridge post:

Posts back in guitar:

Bridge reinserted, noting cut in ring towards front of bridge:

Side view:

I am a very happy owner of a PRS SE Bernie Marsden, but wanted to do something to prevent the wraparound bridge leaning forward in its studs. It does this because the bridge is a little thinner than the gap it locates into and string tension pulls it forward. The loose fit also means that it may fall out of the posts during string changes.

Reading the PRS forums, many users are resorting to locking bridge posts to resolve the issue of bridge tilt, the TonePros set being a popular option (although they have fit issues). I have come up with a much cheaper solution.

I took two of the very thin chromed steel washers that come with volume and tone control pots (I have a drawer full of replaced pots and their fittings; if you don't have any, I bet your nearest guitar repair shop will have lots), and cut once through each washer. The technique is to use wire cutters or pliers to 'score' the ring, then wiggle it either side of the weak point until it breaks. Then pull the two cut edges apart until you have a helical spring. The gap in the washer, that has been pulled open, will just about fit around the bridge post with some persuasion. Then its a matter of aligning the cut to the front of the posts (nearest the pickups) and sliding the bridge back into its slots. Its a nice tight fit and the opened washer acts as a spring washer as the bridge slides in, keeping it held in the posts for future string changes. There is very little, if any, bridge lean once the split washer has been installed.

I can't say if sustain is improved or if 'sitar like buzzing' is banished as I can't say I had noticed any problems with the bridge in the first place. I simply wanted to engineer a solution to the slant and prevent the bridge being loose during string changes.

I hope this helps anyone looking for a cheap solution, or perhaps someone like me who really likes the design, feel and intonation of the PRS SE wraparound bridge but just wants to slightly improve its fit.

Regards,

ibis

Here are some very amateurish pics of the process:

The washers

Scored with cutters:

One wiggled and split:

Persuaded to wrap around bridge post:

Posts back in guitar:

Bridge reinserted, noting cut in ring towards front of bridge:

Side view: